When it comes to selecting a drip edge for your roofing system, there are various options to consider. Understanding the different types of drip edges available will help you make an informed decision based on your specific needs and the requirements of your roof. In this section, we will explore the most common types of drip edges and their characteristics, allowing you to choose the one that best suits your roofing project. From the classic L-shaped drip edge to the versatile custom-bent options, let's delve into the various types of drip edges and their advantages. Additionally, we will discuss the materials used for drip edges, comparing metal and PVC options, among others, to help you determine the most suitable material for your roof. By the end of this section, you will have a comprehensive understanding of the different types of drip edges available, empowering you to make an informed choice for your roofing project.

Types of Drip Edge

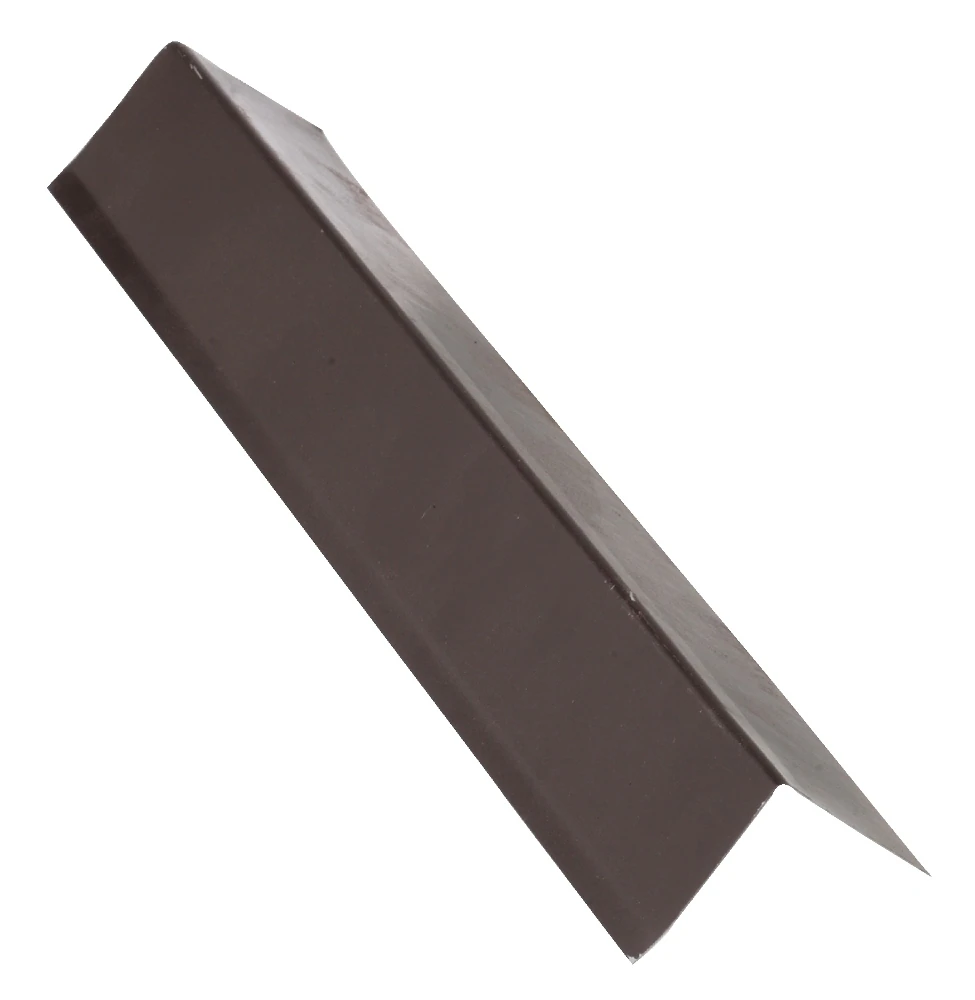

A. L-Shaped Drip Edge: The L-shaped drip edge, also known as a roof edge or eave drip, is the most common type of drip edge used in residential roofing. It features a horizontal flange that rests on the roof deck and a vertical flange that extends down the fascia board. This design effectively directs water away from the roof edge and prevents it from infiltrating the underlying structures.

B. T-Shaped Drip Edge: The T-shaped drip edge, also referred to as a gutter apron, is primarily used in conjunction with gutter systems. It provides an additional layer of protection by extending horizontally over the edge of the roof and vertically against the fascia board. This design helps ensure that water properly enters the gutters, reducing the risk of overflow and water damage.

C. Preformed Drip Edge: Preformed drip edges are manufactured with a specific shape and size, making them ready for installation without requiring customization. They are available in various materials such as metal and PVC and come in standard sizes to fit most roofing applications. Preformed drip edges offer convenience and ease of installation.

D. Custom-Bent Drip Edge: Custom-bent drip edges are created on-site to match the specific dimensions and requirements of a roof. They are often used when dealing with unique roof designs or irregular roof edges. Custom-bent drip edges offer precise fitting and ensure optimal functionality, especially in situations where standard sizes may not suffice.

E. Comparison of Materials: Metal vs. PVC vs. Other Options: Drip edges are commonly available in metal, PVC (polyvinyl chloride), and other materials. Metal drip edges, such as aluminum or galvanized steel, are popular due to their durability, strength, and weather resistance. They are suitable for most roofing applications. PVC drip edges, on the other hand, offer excellent corrosion resistance and are commonly used in areas with high moisture levels. Other options, such as composite materials, may also be available, offering a blend of durability, affordability, and aesthetic appeal.

Understanding the different types of drip edges allows you to select the most appropriate option for your roofing needs.

Comentarios